|

|

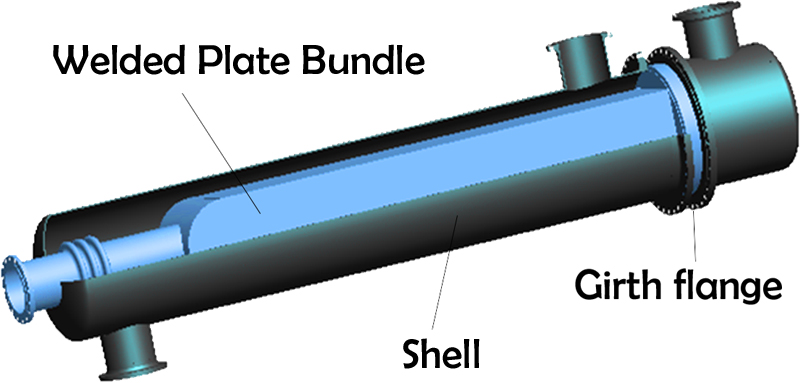

Non-feed/effluent plate & shell heat exchangers

The lanpec Non-feed/effluent plate & shell heat exchanger, basically belongs to the large plate & shell family with a horizontal layout. The exchanger compose of an inner welded plate bundle and an outter pressure vessel shell, work with superior efficiency, high pressure & corrosion resistance and compact structure is an optimum substitute for tubular heat exchangers.

Parameters # Shell diameter: 1 to 3.5 m # Shell total length: 2 to 20 m # Surface area: 100 to 5000 ㎡ # Plate width: 200 to 2000 mm # Plate length: 1 to 16 m # Design pressure: ≤ 8.0 MPa # Design Temp.: ≤ 500 ℃ # Differential pressure ≤ 4.0 MPa (plate bundle) Construction parameter # Plate bundle: SMO 254, Ti, AISI 300 SS, duplex SS, high nickel alloy, etc. # Shell: Carbon steel, stainless steel, Cr-Moly steel etc. # Codes and Standards: ASME, PED, GOST, GB The heat exchanger girth flange design allows disassembly for inspection, maintenance and repairs.Special corrugated plate pattern achieves both high pressure resistance and anti-fouling performance. Applications 1. Atmospheric and vacuum distillation unit 2. Light hydrocarbon recovery unit 3. Fertilizer plan |